Researchers Describe a Method for Producing Nanosheets in Under a Minute

A research group led by Professor Minoru Osada and postdoctoral researcher Yue Shi at Nagoya University in Japan's Institute for Future Materials and Systems (IMaSS) has developed a rapid nanosheet fabrication technology. This innovative method allows for the production of nanosheets, which are ultra-thin films of two-dimensional materials measuring a few nanometres in thickness, in approximately one minute.

This method allows the creation of high-quality, massive nanosheet films with a single click, requiring no specialised knowledge or equipment. Their discoveries are expected to aid in the development of industrial manufacturing processes for various types of nanosheet devices. The research was published in the journal ACS Applied Materials & Interfaces.[1]

Figure .1 Researchers Describe a Method for Producing Nanosheets in Under a Minute

Figure 1 shows Nanosheets are extremely thin films, with thicknesses measured in nanometres. They are too thin to be visible from the side with the naked eye. Nanosheets hold great potential for various applications in fields such as electronics, catalysis, energy storage, and biomedicine. Particularly, nanosheets made from materials like graphene and inorganic substances are being explored for use in diverse devices, including solar cells, sensors, and batteries. This is because they exhibit unique electrical, transparency, and heat-resistant properties that differ from conventional bulk materials. The distinctive characteristics of nanosheets make them promising for advancing technological advancements in multiple domains.

Current techniques employed to fabricate nanosheets, such as the Langmuir-Blodgett method, are associated with skilled operation and complex conditions. Professor Minoru Osada emphasizes that these existing methods require approximately one hour to fabricate a single layer of nanosheets. This time-consuming process creates a significant bottleneck in the manufacturing of nanosheets, hindering their efficient production.

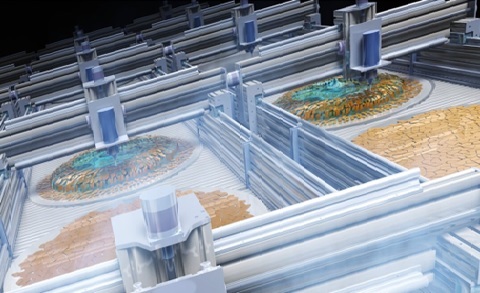

The research group aimed to create a simplified and rapid process for producing high-quality monolayer films of nanosheets. They successfully developed an automated film-forming technique that involved depositing a colloidal aqueous solution onto a heated substrate using an automatic pipette. This process took approximately a minute to complete. Afterward, they aspirated the solution and removed the liquid, resulting in a neatly tiled monolayer film composed of nanosheets. The innovative method ensured there were no gaps between the nanosheets, achieving a uniform and continuous film structure.

Professor Minoru Osada explains that by reducing the surface tension of the colloidal aqueous solution and promoting convection of the nanosheets, they were able to effectively control the alignment of the nanosheets and suppress overlap or gaps between them. This enabled the researchers to have precise control over the construction of multilayer films by repeating the process of fabricating neatly tiled monolayer films. This method allowed for layer-by-layer assembly of nanosheets, providing control over the thickness unit of the resulting multilayer films.

Professor Minoru Osada highlights the significance of the newly developed method, stating that it has the potential to become an important technology for industrial thin-film fabrication and nano-coating of nanosheets. The method is characterized by its simplicity, speed, and the requirement of only a small amount of solution to produce a high-quality, large-area film with a neatly tiled alignment of nanosheets. This innovative approach holds promise for various applications in industries that rely on thin-film fabrication and nano-coating techniques.

Professor Minoru Osada highlights the simplicity and versatility of the technology, stating that it is based on straightforward drop and aspiration operations using an automatic pipette. It does not necessitate specialized knowledge or technology, making it accessible and applicable to various compositions and structures of nanosheets, including oxides, graphene, and boron nitride. Furthermore, the technology allows for film formation on substrates of different shapes, sizes, and materials, making it highly versatile and adaptable.

References:

- https://quillbot.com/?utm_source=freearticlespinner.com&utm_campaign=%2F&utm_medium=extwebp&inputKey=962b624b-2e86-4ab4-baf6-4b144807e8fb

Cite this article:

Janani R (2023),Researchers Describe a Method for Producing Nanosheets in Under a Minute, AnaTechMaz, pp.169