World-First Lab Tests 3D-Printed Space Materials to Help Astronauts Avoid Deadly Impacts in Orbit

World-First Test Facility in Scotland Validates 3D-Printed Space Materials

Interest in space-based 3D printing is rapidly growing, with experts hailing it as a major leap in space exploration and construction. However, a key challenge remains: ensuring these structures can endure the harsh realities of space.

A breakthrough comes with the launch of the NextSpace TestRig, a pioneering facility in Glasgow, Scotland, developed by the University of Glasgow’s James Watt School of Engineering. It's the first dedicated lab globally designed to test the durability of 3D-printed materials intended for use in—or manufactured in—space.

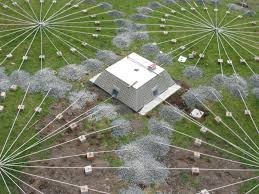

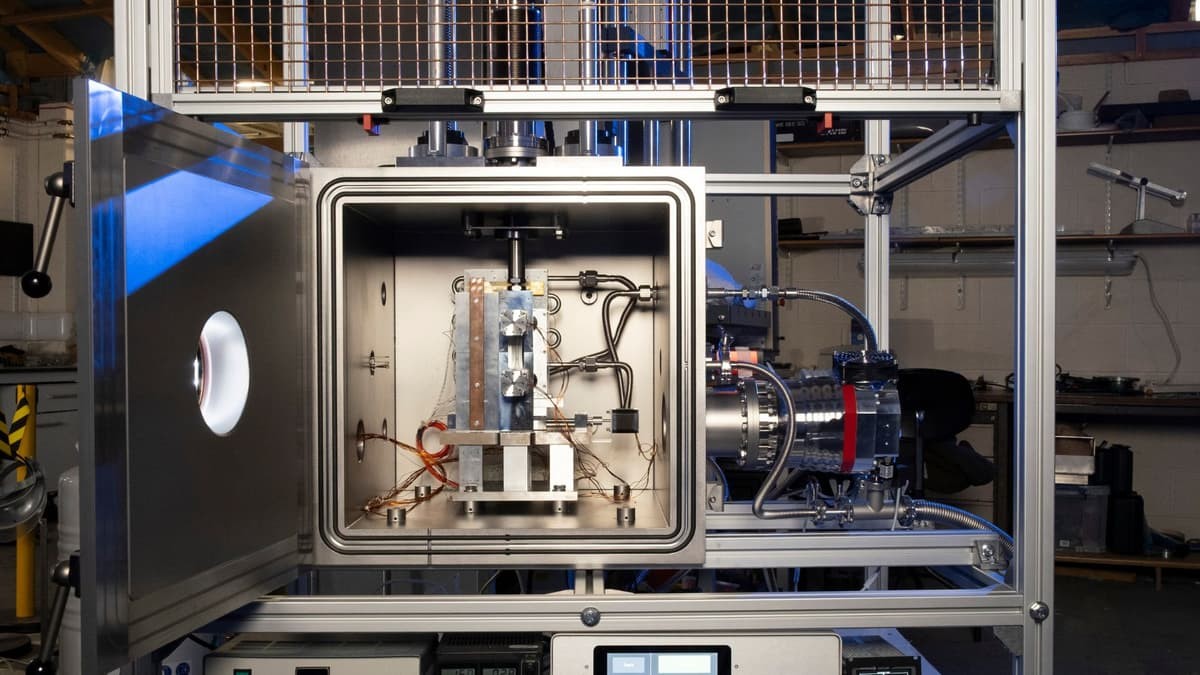

Figure 1. NextSpace TestRig facility.

"The NextSpace TestRig is open to academic researchers and commercial partners worldwide," said Dr. Gilles Bailet, one of the facility’s developers. "It ensures any materials planned for 3D printing in orbit can perform safely."Figure 1 shows NextSpace TestRig facility.

Critical Testing for Space-Ready Materials

Since ordering parts from Earth isn’t feasible, 3D printing offers astronauts the ability to create tools, components, and even habitats on demand using local resources, such as lunar regolith. The concept isn't new—NASA installed a 3D printer on the International Space Station in 2014.

More recently, 2024 saw the first successful in-space metal 3D printing, when the European Space Agency and Airbus printed a stainless-steel S-curve aboard a space station—marking a leap beyond years of plastic-only printing.

Despite these advances, there has never been a dedicated facility to test the reliability of 3D-printed polymers, ceramics, and metals under true space-like conditions—until now.

Preventing Dangerous Space Debris

The vacuum and extreme temperature swings in space can exacerbate flaws in poorly printed materials, potentially causing them to fracture [1]. Fragments could then orbit Earth at bullet-like speeds, posing a serious risk to satellites and spacecraft.

"If a defective piece breaks off, it could orbit Earth at rifle-bullet speeds," said Bailet. "If it strikes another spacecraft, it could cause catastrophic damage and trigger a cascade of space debris."

Simulating Space on Earth

The NextSpace TestRig addresses this risk by replicating the brutal conditions of space. Its vacuum chamber subjects’ materials to temperatures from -150°C (-238°F) to +250°C (500°F). It can also apply forces up to 20 kilonewtons—roughly the weight of two small cars—to test the strength of 3D-printed samples.

This facility represents a crucial step in making space-based 3D printing safer, more reliable, and more sustainable—helping ensure astronauts don’t have to “dodge a bullet” in orbit.

Reference:

- https://interestingengineering.com/innovation/world-first-lab-3d-space-prints-test

Cite this article:

Keerthana S (2025), World-First Lab Tests 3D-Printed Space Materials to Help Astronauts Avoid Deadly Impacts in Orbit, AnaTechMaz, pp.384