Algorithm learns to correct 3D printing errors for different parts, materials and systems

Engineers have created clever 3D printers that may rapidly detect and proper errors, even in beforehand unseen designs, or unfamiliar supplies like ketchup and mayonnaise, by studying from the experiences of different machines.

The engineers, from the College of Cambridge, developed a machine studying algorithm that may detect and proper all kinds of various errors in actual time, and could be simply added to new or current machines to reinforce their capabilities. 3D printers utilizing the algorithm might additionally learn to print new supplies by themselves. [1]

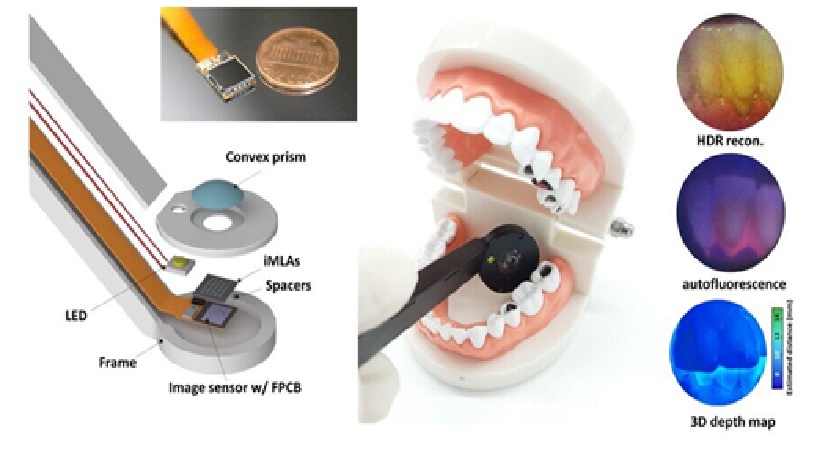

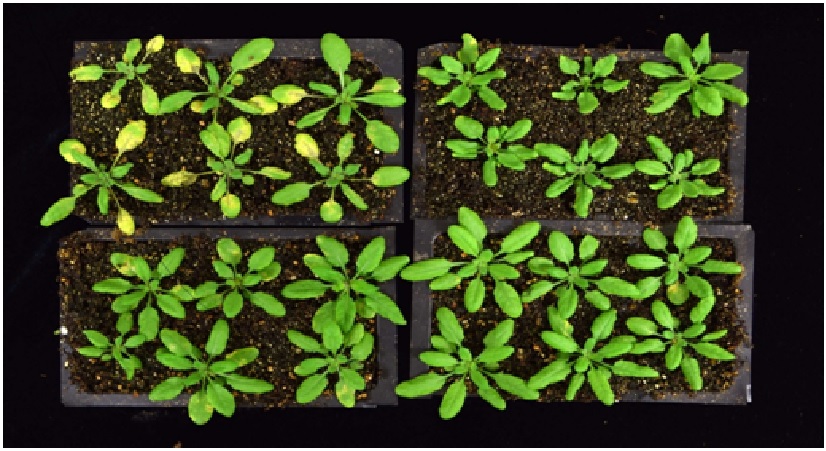

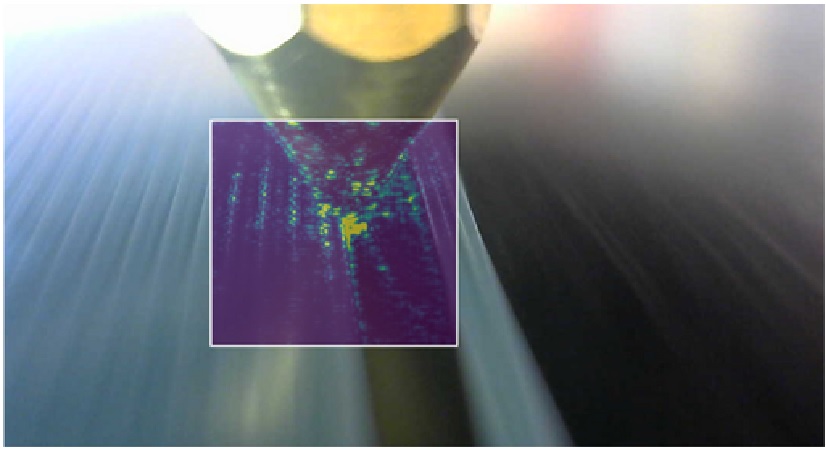

Figure 1. Algorithm learns to correct 3D printing errors for different parts, materials and systems

Figure 1 shows 3D printing has the potential to revolutionize the manufacturing of complicated and customised components, reminiscent of plane elements, customized medical implants, and even intricate sweets, and will additionally remodel manufacturing provide chains. Nevertheless, it’s also weak to manufacturing errors, from small-scale inaccuracies and mechanical weaknesses via to whole construct failures. [2]

Engineers have been developing automated 3D printing monitoring, but existing systems can only detect a limited range of errors in one part, one material and one printing system.

The researchers trained a deep learning computer vision model by showing it around 950,000 images captured automatically during the production of 192 printed objects. Each of the images was labelled with the printer's settings, such as the speed and temperature of the printing nozzle and flow rate of the printing material. The model also received information about how far those settings were from good values, allowing the algorithm to learn how errors arise. [3]

As a result, an algorithm trained using only one type of material and printing system was able to detect and correct errors in a variety of materials, from engineering polymers to even ketchup and mayonnaise, on different types of printing systems.

Later trained algorithm can be more efficient and reliable than a human operator in detecting errors. This can be important for quality control in applications where component failure can have serious consequences.

With the support of Cambridge Enterprise, the university’s commercialization arm, Brion has created Matta, a spin-off company that will develop the technology for commercial applications. [4]

References:

- https://dailyinformat.com/2022/08/16/algorithm-learns-to-correct-3d-printing-errors-for-different-parts-materials-and-systems/? utm_source=rss&utm_medium=rss&utm_campaign=algorithm-learns-to-correct-3d-printing-errors-for-different-parts-materials-and-systems

- https://news8plus.com/algorithm-learns-to-correct-3d-printing-errors-for-different-parts-materials-and-systems/

- https://www.sciencedaily.com/releases/2022/08/220816142751.htm

- https://newjerseyupdates.com/the-algorithm-learns-to-correct-3d-printing-errors-for-different-parts-materials-and-systems/82751/

Cite this article:

Thanusri swetha J (2022), Algorithm learns to correct 3D printing errors for different parts, materials and systems, AnaTechMaz, pp.92