First 3D-Printed, Flexible OLED Display Technology

In a ground breaking new study, researchers at the University of Minnesota Twin Cities used a customized printer to fully 3D print a flexible organic light-emitting diode (OLED) display. The discovery could result in low-cost OLED displays in the future that could be widely produced using 3D printers by anyone at home, instead of by technicians in expensive microfabrication facilities. [1]

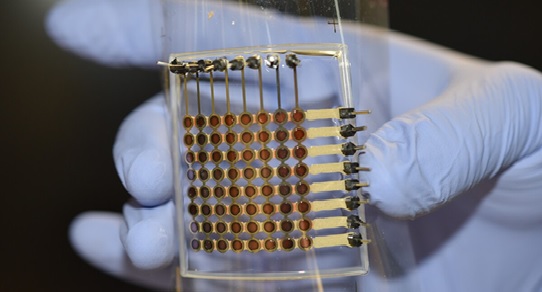

Figure 1. First 3D-Printed, Flexible OLED Display Technology

Figure 1 shows the OLED display technology is based on the conversion of electricity into light using an organic material layer. OLEDs function as high quality digital displays, which can be made flexible and used in both large-scale devices such as television screens and monitors as well as handheld electronics such as smartphones. OLED displays have gained popularity because they are lightweight, power-efficient, thin and flexible, and offer a wide viewing angle and high contrast ratio. For further information see the IDTechEx report on Flexible, Printed OLED Displays 2020-2030: Forecasts, Markets, Technologies. [1]

So, researchers from the University of Minnesota created a fully 3D printed flexible OLED display, which can be built at home by anyone using 3D printers, thus saving costs. With the some amazing advancements made over the period and the 3D printing hardware industry set to witness a US$ 9.9 billion growth in the future, the news is exciting as it allows one to build monitors for both large and small electronic devices.

“OLED displays are usually produced in big, expensive, ultra-clean fabrication facilities,” said Michael McAlpine, professor in the Department of Mechanical Engineering at the University of Minnesota. “We wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.” [2]

The proof-of-concept finished product takes the form of a square display measuring about 1.5 inches (38 mm) per side and incorporating a grid of 64 pixels, each one of which emits light. It continued to work over the course of 2,000 bending cycles, suggesting that it may be well-suited to use in wearables or other soft electronics.

McAlpine, Su and colleagues now plan on increasing both the resolution and the brightness of the display. They believe that the technology could make its way into real-world use relatively soon.

The nice part about our research is that the manufacturing is all built in, so we're not talking 20 years out with some 'pie in the sky' vision, says McAlpine. This is something that we actually manufactured in the lab, and it is not hard to imagine that you could translate this to printing all kinds of displays ourselves at home or on the go within just a few years, on a small portable printer. [3]

References:

- https://www.printedelectronicsworld.com/articles/25639/first-fully-3d-printed-flexible-oled-display

- https://www.electronicsforu.com/news/whats-new/first-3d-printed-flexible-oled-display-technology

- https://newatlas.com/3d-printing/worlds-first-3d-printed-flexible-oled-display/

Cite this article:

Thanusri swetha J (2022), First 3D-Printed, Flexible OLED Display Technology, pp. 82