A Single Drop Revolutionizes Nanosensor Manufacturing

Nanosensor manufacturing is on the brink of a groundbreaking transformation, thanks to pioneering research by engineers at Macquarie University. In a game-changing breakthrough, a team of experts has unveiled a novel technique that promises to significantly reduce carbon emissions, slash costs, enhance efficiency, and amplify versatility in the trillion-dollar nanosensor industry.

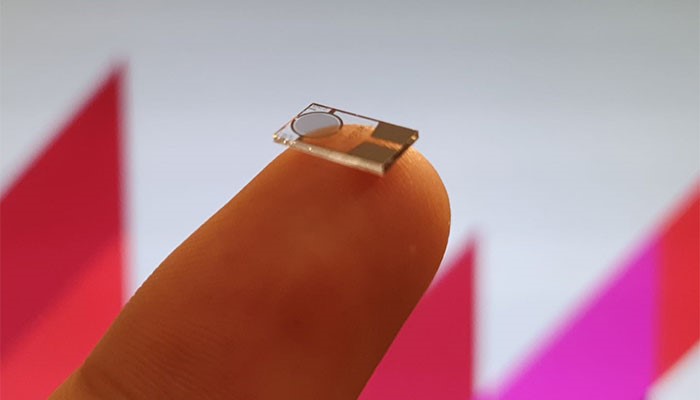

Figure 1. Nanosensor.

Traditionally, crafting nanosensors involves intricate processes and high temperatures, making it an energy-intensive endeavor. However, the Macquarie University team has a new approach that involves treating each sensor with a mere droplet of ethanol. This innovative method, detailed in their recent publication titled "Capillary-driven self-assembled microclusters for highly performing UV detectors" in the Journal of Advanced Functional Materials, opens the doors to a more sustainable and accessible nanosensor manufacturing process.

Associate Professor Noushin Nasiri, the head of Macquarie University's Nanotech Laboratory, explains the significance of this advancement. She notes that conventional nanosensor fabrication often results in nonfunctional sensors due to gaps between nanoparticles that prevent effective electrical signal transmission. These gaps arise from weak natural bonds that form when billions of nanoparticles are deposited onto a sensor surface. The team's discovery addresses this challenge and promises a fundamental shift in nanosensor production.

The origins of this revolutionary technique stem from the team's efforts to enhance ultraviolet (UV) light sensors, a technology integral to Sunwatch, a project that earned Associate Professor Nasiri a prestigious spot as a 2023 Eureka Prize finalist. In the pursuit of improving UV light sensors, the team stumbled upon a method that bypasses the arduous heating process typically required to fuse layers of nanoparticles. This process, which involves 12 hours of energy-intensive heating, often renders many materials unsuitable for nanosensor production.

The groundthrough centers on a single droplet of ethanol, which, when applied to the sensor's surface, triggers a transformative reaction. Unlike the traditional heat-based fusion, ethanol application induces movement among surface atoms of nanoparticles, effectively eliminating the gaps between them. This leads to improved sensor efficiency and responsiveness, surpassing the outcomes achievable through prolonged heating.

The accidental discovery of this technique is credited to Jayden (Xiaohu) Chen, a postgraduate student and the study's lead author. While washing a crucible, Chen inadvertently splashed ethanol onto a sensor, an incident that would typically spell disaster for such delicate devices. However, what followed defied expectations: the sensor outperformed all previous samples, setting the stage for a revolution in nanosensor manufacturing.

Associate Professor Nasiri emphasizes that the success of this method hinged on meticulous experimentation to pinpoint the optimal ethanol volume. Inspired by the "Goldilocks" principle, the team determined that three microliters were insufficient, while ten microliters proved excessive and detrimental. The sweet spot, as demonstrated by their rigorous testing, was found at five microliters of ethanol.

The potential impact of this discovery is immense, reverberating throughout the nanosensor industry. Patents for the technique are already pending, indicative of its far-reaching implications. Notably, this innovation isn't limited to UV sensors alone; it extends to sensors detecting carbon dioxide, methane, hydrogen, and more.

Activated within minutes by a precisely measured droplet of ethanol, the sensors undergo a remarkable transformation, converting a previously sluggish and resource-intensive process into a streamlined and efficient operation. Industry players in Australia and beyond are eager to collaborate with Associate Professor Nasiri and her team to translate this technique into practical applications.

In essence, a single drop of ethanol has set in motion a nanosensor revolution, propelling the industry toward a future marked by enhanced sustainability, reduced costs, and unprecedented efficiency. The potential of this technique is boundless, promising to reshape the landscape of nanosensor manufacturing on a global scale.

Source: Macquarie University

Cite this article:

Hana M (2023), A Single Drop Revolutionizes Nanosensor Manufacturing, AnaTechmaz, pp.484