Revolutionizing Green Hydrogen: Unleashing Cost-Cutting Technologies for Sustainable Energy Future

Researchers at the Korea Institute of Science and Technology (KIST) have made significant advancements in reducing the production cost of green hydrogen. Green hydrogen, which is produced without fossil fuels and carbon dioxide emissions, has great potential in achieving a decarbonized economy. However, the high cost of water electrolysis devices used to produce green hydrogen has been a major barrier to its widespread adoption. [1]

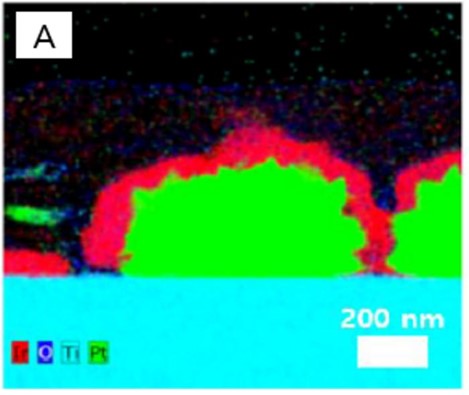

Figure 1. Catalyst shapes.

Figure 1 shows Catalyst shapes made with conventional technology (red-iridium catalyst/green-platinum). Led by Dr. Hyun S. Park and Sung Jong Yoo, the research team has developed a groundbreaking technology that drastically reduces the usage of precious metals, such as iridium and platinum, in polymer electrolyte membrane water electrolysis devices. The team's approach involves replacing the expensive platinum and gold materials in the electrode protection layer with cost-effective iron nitride. By uniformly coating a small amount of iridium catalyst on top of the iron nitride layer, the researchers have achieved performance and durability comparable to existing devices, while significantly enhancing the economic efficiency of the electrolysis process. [1]

Polymer electrolyte membrane water electrolysis devices play a vital role in producing high-purity hydrogen and oxygen by decomposing water using renewable energy sources like solar power. These devices are crucial for supplying hydrogen to various industries, including steelmaking and chemicals, as well as for energy conversion and hydrogen storage purposes. [1]

In conventional electrolysis devices, a protective layer of gold or platinum is applied to the oxygen generating electrode to ensure durability and efficiency. Additionally, a layer of iridium catalyst is coated on top of the protective layer. The scarcity and limited production of these precious metals have been major obstacles in the widespread adoption of green hydrogen production technologies. [1]

To address this challenge, the research team successfully replaced the expensive gold and platinum protective layer with cost-effective iron nitride (Fe2N). They developed a composite process that uniformly coats the electrode with iron oxide, followed by its conversion to iron nitride to enhance conductivity. The team also established a process to uniformly apply a 25-nanometer-thick layer of iridium catalyst on top of the iron nitride protective layer, significantly reducing the amount of iridium catalyst to less than 0.1 mg/cm2. As a result, they achieved a highly efficient and durable electrode for hydrogen production. [1]

The newly developed electrode, which substitutes precious metals with non-precious metal nitrides, exhibits similar performance to existing commercial electrolysis units. Moreover, it reduces the amount of iridium catalyst to just 10% of the previous level. The team conducted over 100 hours of operation to verify the initial stability of the electrolysis unit with the new components. [1]

Dr. Hyun S. Park of KIST emphasized the importance of reducing the amount of iridium catalyst and finding alternative materials for the platinum protective layer to achieve economic viability and widespread adoption of polymer electrolyte membrane green hydrogen production devices. The utilization of cost-effective iron nitride instead of platinum holds significant promise. The team plans to further evaluate the performance and durability of the electrode and intends to apply it to commercial devices in the near future. [1]

Source: EurekAlert

References:

- https://www.eurekalert.org/news-releases/991096

Cite this article:

Hana M (2023), Revolutionizing Green Hydrogen: Unleashing Cost-Cutting Technologies for Sustainable Energy Future, AnaTechmaz, pp.453