Revolutionizing 2D Materials: Introducing KISS, the Key to Large, Clean and Versatile Single-Layer Synthesis!

The remarkable discovery of graphene, the two-dimensional form of graphite, nearly two decades ago ignited a tremendous surge in the exploration of 2D materials and their unique physical properties. Initially, graphene was obtained by meticulously exfoliating bulk graphite using sticky tape—an achievement that earned its discoverers a Nobel Prize. However, this approach is not without its limitations. Addressing these challenges, an international team of surface scientists has devised a straightforward method to fabricate large and pristine 2D samples from a diverse range of materials, employing three distinct substrates. Described as kinetic in situ single-layer synthesis (KISS), this groundbreaking technique was detailed in the esteemed journal Advanced Science on 1 June. [1]

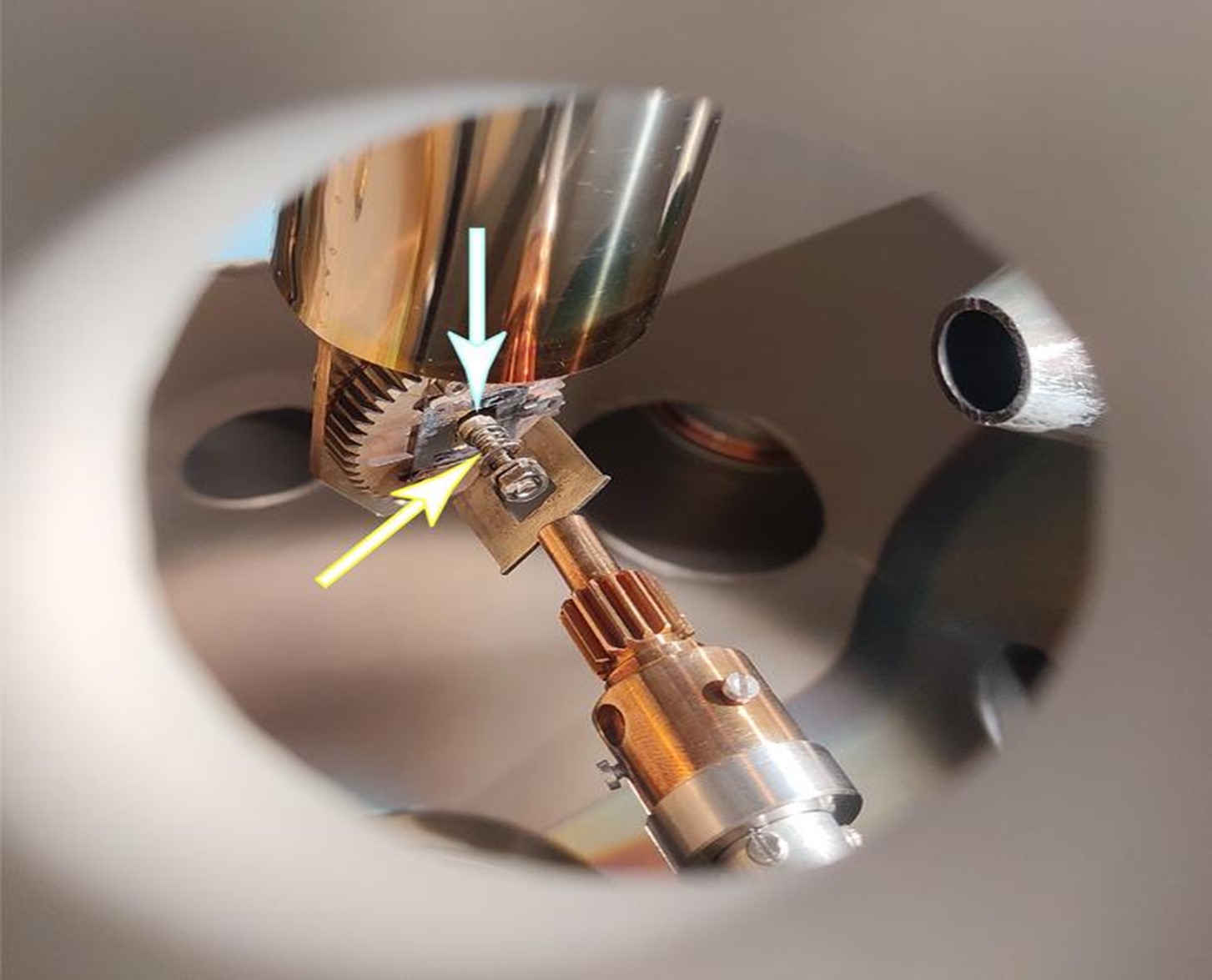

Figure 1. The set-up for kinetic in situ single-layer synthesis (KISS).

Figure 1 shows the set-up for kinetic in situ single-layer synthesis (KISS). The bulk material is placed on a sample holder with a spring to regulate the impact (yellow arrow). It is then pressed against the gold crystal (the slightly brighter ring below the blue arrow). After release, a 2D layer will be attached to the gold substrate. In comparison to bulk materials, 2D materials exhibit distinctive properties attributed to the confinement of charge carriers. The production of such materials can be achieved through two primary approaches: exfoliation of larger crystals or growth of a single-layer structure. The exfoliation process involves painstakingly peeling away layers from a larger crystal until only one layer remains. Antonija Grubišić-Čabo, a surface scientist at the University of Groningen (the Netherlands) and the first author of the Advanced Science publication, explains, "This method is time-consuming and demands specialized skills and equipment. Additionally, it often yields minuscule flakes, while the adhesive tape employed can leave behind polymer residues on their surfaces." [1]

Gold

Unleashing the potential of growing 2D films presents another avenue for producing large samples with precise control. However, this approach often demands significant time and effort to optimize growth conditions, with the outcome not always yielding flawless layers. Grubišić-Čabo highlights this challenge, stating, "It often takes a considerable amount of time to develop suitable growth methods for 2D materials, and even then, obtaining a perfect layer is not guaranteed." Motivated to overcome these obstacles, Grubišić-Čabo and Maciej Dendzik, the last author of the study, assembled a remarkable team comprising former colleagues who had collaborated during their PhD studies at Aarhus University (Denmark). Together, they set out to devise a straightforward technique for the production of 2D materials. [1]

While aware of previous experiments utilizing gold films for exfoliation purposes, these experiments predominantly took place in ambient air, rendering them unsuitable for air-sensitive materials and surface science research. The team aimed to develop a technique capable of generating air-sensitive 2D materials on various substrates. In their initial endeavor, they employed a gold crystal within a high vacuum chamber. Grubišić-Čabo explains, "Essentially, we applied force to the crystal against the bulk material and made an intriguing observation—a pristine 2D layer adhered to the gold." Although the precise mechanism behind this phenomenon remains unclear, the team speculates that the bond formed with the gold is stronger than the Van der Waals forces responsible for maintaining the layers within the bulk crystal structure. [1]

Devices

Building upon their initial experiment, the team implemented an innovative addition to the setup—a spring integrated into the stage containing the bulk material. This spring acted as a shock absorber, enabling enhanced control over the impact of the gold crystal. Moreover, the researchers demonstrated that both silver and the semiconductor germanium could serve as substrates for peeling off 2D materials. Grubišić-Čabo notes, "Gold crystals are commonly found in surface science labs, where they are utilized for instrument calibration, among other purposes. Scientists are hesitant to damage these crystals, but in our experiments, that was not an issue. Additionally, we have modified the protocol to employ single crystal gold thin films, which offer the advantage of being dissolvable, thus enabling isolation of the 2D sample, as long as it remains stable in air or liquid." [1]

The isolated samples obtained through this technique serve as a crucial stepping stone for the subsequent stage: constructing devices utilizing the 2D materials produced via the KISS method. Grubišić-Čabo acknowledges, "While this is not currently feasible, it is an area we are actively exploring. Presently, our technique allows for the production of exceptionally clean and large 2D samples in a remarkably simple manner, enabling the creation of air-sensitive 2D materials. Furthermore, our approach utilizes standard equipment that is readily available in almost every surface science laboratory." [1]

Source: EurekAlert

References:

- https://www.eurekalert.org/news-releases/990778

Cite this article:

Hana M (2023), Revolutionizing 2D Materials: Introducing KISS, the Key to Large, Clean and Versatile Single-Layer Synthesis!, AnaTechmaz, pp.449