Environmentally Friendly 3D-Printed Polymers

Dr. Emily Pentzer,research is a collaborative effort that includes researchers from the Texas A&M College of Engineering, the Texas A&M Engineering Experiment Station, the Texas A&M Department of Chemistry and the University of Kashmir, is making 3D-printed polymers more environmentally friendly through a process that allows the polymers to naturally degrade over time.

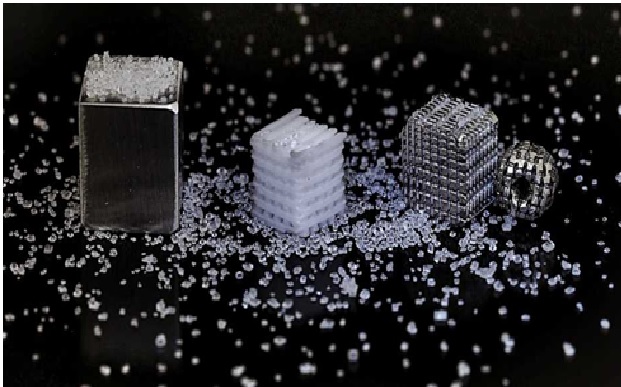

Figure 1: 3D-printed polymers that naturally degrade.

Figure 1 shows thatmost commercial synthetic polymers consist of large molecules that do not break apart under normal conditions. When left in the environment, manufactured items such as Styrofoam cups or plastic containers break down into small pieces that are unseen by the naked eye, but the long polymer molecules remain present forever. [1]

"Our goal was to create sustainable degradable polymeric structures," Pentzer said. "We did this by leveraging the microstructures afforded by chemistry in conjunction with the macrostructures afforded by 3D printing."

Most commercial synthetic polymers consist of large molecules that do not break apart under normal conditions. When left in the environment, manufactured items such as Styrofoam cups or plastic containers break down into small pieces that are unseen by the naked eye, but the long polymer molecules remain present forever. [2]

On the production of degradable polymers, Pentzer collaborated with Dr. Don Darensbourg, Distinguished Professor in the Department of Chemistry at Texas A&M, to use carbon dioxide and table salt to create the ink that was used in 3D printing process.

After printing, the structures are washed with water to dissolve the salt and solidify the structure. While the outside of the structure continues to look smooth, the process creates thousands of tiny pores that allow the chemical compounds to degrade more quickly.

“Under the right conditions, the polymers we made break down really quickly,” Pentzer said. “Ideally, they will break down into small molecules that are not toxic. Those smaller molecules won’t be able to carry things like heavy metals or bacteria.”He also sees a bright future for 3D-printed polymers in biomedicine.

“These materials can be used for a variety of biomedical applications,” Pentzer said. “Things like scaffolding for implants that degrade over time, so your body can heal, but you won’t have that piece of plastic in you forever.”

References:

- https://phys.org/news/2022-10-3d-degradable-polymers-salt.html

- https://news.knowledia.com/GB/en/articles/researchers-3d-print-degradable-polymers-using-salt-95ab91849447e7f9ef432d2e976d8d6703967114

- https://tadalafilarb.com/researchers-3d-print-degradable-polymers-using-salt/

Cite this article:

Sri Vasagi K (2022) Environmentally Friendly 3D-Printed Polymers, Anatechmaz, pp. 420