New Chemically Designed Next Generation Carbon Fiber from Waste

The group of Joshua Yuan, professor and chair of the Department of Energy, Environmental & Chemical Engineering at Washington University in St. Louis' McKelvey School of Engineering, designedHigh Molecular Weight Esterified Linkage Lignin (HiMWELL). The key to opening up lignin's potential was chemically altering some of its properties.

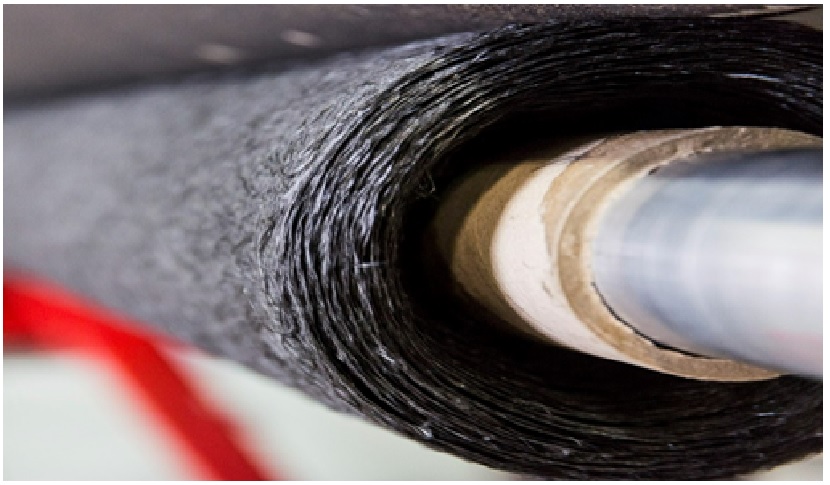

Figure 1: HiMWELL design considered a product waste from industry.

Figure 1 shows that, new research led to lighter, stronger carbon fiber materials and stronger plastics with a gentler environmental impact. The main ingredient necessary for these improvements is lignin, a compound that is essential for most plants but considered a waste product by industry. [1]

Researchers knew that, combined with polyacrylonitrile (PAN), the newly designed HiMWELL lignin could become a precursor to a better carbon fiber and that it could enable the development of recyclable plastics with better properties, as well.

Already, carbon fiber is known for being a strong and stiff, yet light — and premium — material. It is used as structural reinforcement in everything from tennis rackets to airplanes, and carbon fiber frames reduce weight and improve safety in high-end vehicles. It has been incorporated anywhere possible in some of the fastest super and hypercars.

Yuan’s previous work identified three main roadblocks to incorporating lignin in the equation: neither lignin’s chemical structure nor its molecular weight is uniform, which makes it difficult to combine with other polymers. And it has a high number of OH groups, a reactive pairing of oxygen and hydrogen that attracts water — not ideal for building a rigid material like carbon fiber.

These discoveries inspired Yuan and Jinghao Li, a senior scientist at Washington University, to redesign lignin structures. [2]By processing a method to chemically change these properties, Yuan said, "We've truly created a benignant of lignin that is precise unique."

When combined with PAN, the HiMWELL-based c fibre had a grounds tensile spot and showed amended mechanical properties than modular c fiber. When it was added to recyclable polymer blends, HiMWELL improved mechanical properties and besides improved UV protection.

"Finally, we person a technological way for lignin to beryllium utilized for c fibers," Yuan said. And possibly 1 day, "You'll crook this discarded into the ammunition of a car."The U.S. Department of Energy's Office of Energy Efficiency & Renewable Energy and Bioenergy Technologies Office supported the work. [3]

References:

- https://www.sciencedaily.com/releases/2022/08/220818141804.htm

- https://source.wustl.edu/2022/08/by-design-from-waste-to-next-gen-carbon-fiber/

- https://mondaydaily.com/by-design-from-waste-to-next-gen-carbon-fiber-42415.html

Cite this article:

Sri Vasagi K (2022) New Chemically Designed Next Generation Carbon Fiber from Waste, Anatechmaz, pp. 413