Nanostructured, High-Performance Alloy Developed using 3D-Printing

Utilising a laser-based 3D printing technique, researchers from the University of Massachusetts Amherst and the Georgia Institute of Technology have developed a nanostructured high-entropy alloy that is far more ductile and stronger than other state-of-the-art additively manufactured materials. This could pave the way for building higher-performance components used in aerospace, energy, medicine, and transportation. Such high entropy alloys (HEA) have gained popularity in material science. They have five or more elements in near-equal proportions and enable to create near-infinite number of unique combinations in designing alloys. [1]

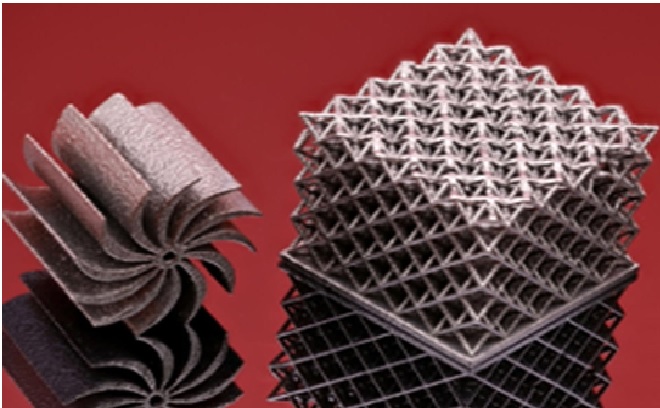

Figure 1. Nanostructured, High-Performance Alloy Developed using 3D-Printing

Figure 1 shows 3D printing, which is also known as additive manufacturing, has recently emerged as a powerful approach to material development. Laser-based 3D printing can produce large temperature gradients and high cooling rates that are not readily accessible by conventional routes. However, “the potential of harnessing the combined benefits of additive manufacturing and HEAs for achieving novel properties remains largely unexplored,” says Zhu. [2]

“This unusual microstructure’s atomic rearrangement gives rise to ultrahigh strength as well as enhanced ductility, which is uncommon, because usually strong materials tend to be brittle,” Chen says. Compared to conventional metal casting, “we got almost triple the strength and not only didn’t lose ductility, but actually increased it simultaneously,” he says. “For many applications, a combination of strength and ductility is key. Our findings are original and exciting for materials science and engineering alike.” [3]

“Our simulation results show the surprisingly high strength yet high hardening responses in the BCC nanolamellae, which are pivotal for achieving the outstanding strength-ductility synergy of our alloy. This mechanistic understanding provides an important basis for guiding the future development of 3D printed HEAs with exceptional mechanical properties,” Zhu says.

In addition, 3D printing offers a powerful tool to make geometrically complex and customized parts. In the future, harnessing 3D printing technology and the vast alloy design space of HEAs opens ample opportunities for the direct production of end-use components for biomedical and aerospace applications. [4]

References:

- https://gadgets360.com/science/news/3d-printed-nanostructured-high-entropy-alloy-developed-high-ductility-strength-3224760

- https://scitechdaily.com/first-3d-printed-high-performance-nanostructured-alloy-thats-both-ultrastrong-and-ductile/

- https://www.amchronicle.com/news/researchers-3d-print-first-high-performance-nanostructured-alloy-thats-both-ultrastrong-and-ductile/

- https://indiaeducationdiary.in/georgia-institute-of-technology-researchers-3d-print-first-high-performance-nanostructured-alloy-thats-both-ultrastrong-and-ductile/

Cite this article:

Thanusri swetha J (2022), Nanostructured, High-Performance Alloy Developed using 3D-Printing, Anatechmaz, pp. 366