Copper 3D Printing with Sub-micron Resolution

High-quality data transmission, high-precision information sensing, and high-sensitivity signal detection are important means to achieve precise perception and effective identification. High-performance chips, terahertz transmission T/R components, and extreme environment sensor manufacturing technologies have become key frontier research hotspots. Its effective implementation strongly depends on the ultra-precision micro-nano manufacturing level of the complex microstructure of core functional devices. As an excellent carrier for information-enabled core functional devices, pure copper metal has ultra-high electrical conductivity, thermal conductivity, and high ductility, as well as low-loss signal transmission capabilities. [1]

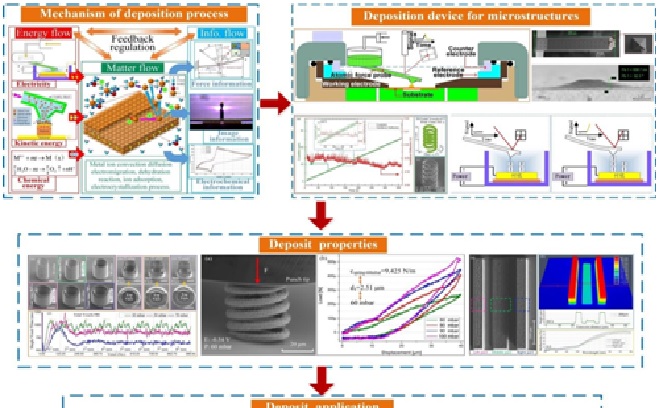

Figure 1. Copper 3D Printing with Sub-micron Resolution

Figure 1 shows Professor Huadong Yu (a professor of Jilin University, and the chief technology officer of Key Laboratory of Cross-scale Micro-Nano Manufacturing of Ministry of Education), Jinkai Xu ( a professor of CUST and the director of the National and Local Joint Engineering Laboratory of Precision Manufacturing and Detecting Technology/Key Laboratory of Cross-scale Micro-Nano Manufacturing of the Ministry of Education, and the leader of the micro-nano manufacturing discipline of CUST.), and Wanfei Ren (a lecturer of CUST) have developed a few methods for manufacturing of microstructures. [2]

“The authors on this paper proposed a mathematical mannequin of the synergy of pulsed micro-jet, focusing electrical induction and atomic drive servo. Though preliminary, this mannequin establishes the preliminary mannequin of electrochemical deposition, materials transport and drive info suggestions.” [3]

“The machine used within the experiment are from Exaddon AG, Switzerland. The operate of the machine is to observe the state of the deposition course of through the experiment. Because of the machine, the Z-direction place of the atomic power probe and the bending state of the cantilever could be detected on-line on the similar time.” [4]

References:

- https://www.eletimes.com/copper-3d-printing-with-sub-micron-resolution

- https://phys.org/news/2022-07-advanced-pure-copper-3d-sub-micron.html

- https://frpbypassfree.com/superior-pure-copper-3d-printing-with-sub-micron-decision/

- https://ilmiwap.com/advanced-pure-copper-3d-printing-with-sub-micron-resolution/

Cite this article:

Thanusri swetha J (2022), Copper 3D Printing with Sub-micron Resolution, Anatechmaz, pp. 357