New System for Removing Hydrogen Gas from Liquid Carriers

Researchers from North Carolina State University have developed a new technique for extracting hydrogen gas from liquid carriers which is faster, less expensive and more energy efficient than previous approaches.

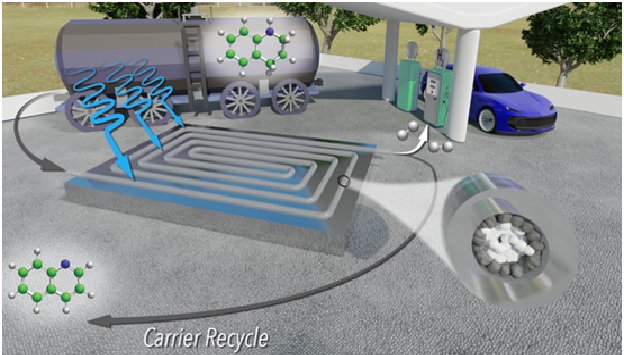

Figure 1: technique for extracting hydrogen gas from liquid carries.

Figure 1 shows that "Hydrogen is widely viewed as a sustainable energy source for transportation, but there are some technical obstacles that need to be overcome before it can be viewed as a practical alternative to existing technologies," says Milad Abolhasani, and NC State. [1]

Hydrogen fuel does not result in CO2 emissions. Also, hydrogen refuelling stations can be situated at existing gas stations. This takes advantage of existing infrastructure. However, transporting hydrogen gas is hazardous, so hydrogen has to be transported through a liquid carrier.

A major factor that contributes to the success of the new method is that it is a continuous-flow reactor. The reactor matches a thin, clear tube packed with sand. The “sand” includes micron-scale grains of titanium oxide, in which many are coated with rhodium.

The hydrogen-carrying liquid has been pumped into one end of the tube. The rhodium-coated particles will line the tube’s outer part, where it is possible for the sunlight to reach them. Such particles are photoreactive catalysts that, in the existence of sunlight, tend to react with the liquid carrier to liberate hydrogen molecules as a gas.[2]

The researchers precisely engineered the system so that only the outer grains of titanium oxide are coated with rhodium, ensuring the system uses no more rhodium than is necessary.“In a conventional batch reactor, 99% of the photocatalyst is titanium oxide and 1% is rhodium,” Abolhasani says. “In our continuous flow reactor, we only need to use 0.025% rhodium, which makes a big difference in the final cost. In their prototype reactor, the researchers were able to achieve a 99% yield.

“That’s eight times faster than conventional batch reactors, which take 24 hours to reach 99% yield,” Ibrahim says. “And the system should be easy to scale up or scale out to allow for catalyst reuse on commercial scale—you can simply make the tube longer or merge multiple tubes running in parallel.”

The flow system can run continuously for up to 72 hours before its efficiency decreases. At this point, the catalyst can be “regenerated” without removing it from the reactor—it’s a simple cleaning process that takes about six hours. The system can then be restarted and run at full efficiency for another 72 hours.NC State has filed a provisional patent for the technology.

References:

- Source:https://www.sciencedaily.com/releases/2022/05/220523115413.htm

- Source:https://www.azocleantech.com/news.aspx?newsID=31743

- Source:https://www.futurity.org/hydrogen-gas-renewable-fuels-energy-2743572/

Cite this article:

Sri Vasagi K (2022), New System for Removing Hydrogen Gas from Liquid Carriers, Anatechmaz, pp. 318