Innovative Thermal Management Solution for EVs

Hella has unleashed an innovative coolant hub solution that can revolutionize thermal management in electric vehicles (EVs). Looking at the steady increase in the electrification of the automobiles and the importance of efficient thermal management in electric vehicles, HELLA has come out with a Coolant Control Hub, an innovative subsystem that it says can revolutionize thermal management in the vehicle.

The solution combines all the necessary functions for efficient thermal management for the first time in the form of a subsystem. An innovative 7-way valve ensures ideal temperature of battery, components and vehicle interior at any time of the year and enables efficient heat recovery. A modular approach allows components to be combined according to requirements. [1]

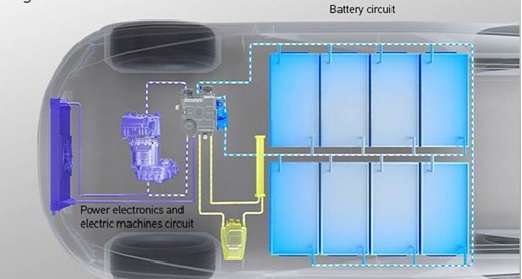

Figure 1. Innovative Thermal Management Solution for EVs

Figure 1 shows the latest report from IDTechEx on Thermal Management for Electric Vehicles details the OEM strategies, trends and emerging alternatives around the thermal management of Li-ion batteries, electric traction motors and power electronics. The technologies and strategies currently in use are described, analysed and forecast. Emerging alternatives like immersion cooling are also addressed and discussed for their suitability in future applications along with adoption forecasts. All forecasts are given through to 2031 and include quantities such as EV battery demand, battery thermal management strategy, thermal interface materials, electric motor demand and Si IGBT or SiC MOSFET inverters. [2]

Electric vehicles (EVs) are the future of the automotive industry; unfortunately, 2020 appears to have been the year of the EV recall due to battery fires. In China, 10,579 battery electric vehicles (BEVs) and plug-in hybrids (PHEVs) have been recalled due to fire hazards across 7 OEMs (January to October). General Motors has recalled 68,667 Chevrolet Bolts, telling owners not to park their cars near their house or in their garage for risk of fire. This has not just been limited to a few OEMs either. [3]

Modular design approach

HELLA’s Coolant Control Hub (CCH) is based on a modular principle and, in its highest level of integration, connects three circuits with each other in the vehicle: the battery, interior electronics as well as the power electronics and electric motor circuit.

“What they all have in common is a significant reduction in components, which means that logistics and overall costs for installing the vehicle can be reduced – a major advantage for manufacturers,” says Twiehaus.

In addition, the centralization leads to an ideal distribution of thermal energy in the vehicle. The precise order of magnitude after optimization depends on the respective architecture and layout of the customer. “We configure a custom product for our customers according to the platform architecture of the vehicle,” Twiehaus explains.

For example, CCH combines multi-way valves, actuators, distribution systems, electronic circulation pumps, expansion tanks and heat exchangers as well as sensors in one product. “This allows for significant improvements in the structure and number of individual components such as actuators and water lines.” [1]

References:

- https://www.electronicsforu.com/news/new-products/evs

- https://www.idtechex.com/en/research-report/thermal-management-for-electric-vehicles-2021-2031/822

- https://www.prnewswire.com/news-releases/thermal-management-in-2020-highlights-from-idtechex-301185939.html

Cite this article:

Thanusri swetha J (2022), Innovative Thermal Management Solution for EVs, pp. 105